A well designed and operated heat-transfer-fluid system is a key feature of a safe, reliable and cost-effective heating design. However, problems can arise if the heat-transfer fluid becomes heavily degraded or the system is allowed to accumulate solids and other process contaminants.

Avoiding heat-transfer fluid degradation and contamination often requires the use of the following filtration, flushing and cleaning techniques.

Filtration

In many cases, filtration can effectively remove solids that, if left unchecked, may result in the need to drain and flush a system. In general, glass-fiberwound

filter cartridges work well for in-system filtration of organic-liquid heat-transfer fluids.

These filters are generally available from numerous manufacturers, are usable at temperatures up to 400°C, typically have adequate solids-holding capacity and are usually economical and disposable.

The filter housing should also be specified for the desired temperature and pressure.

The filter should be installed where there is a 20–40-psi pressure drop, and should have a maximum throughput of 1% of the system flowrate. For initial startup, a 100-μm-nominal particle removal rating is acceptable, and can be gradually reduced to a 10-μm-rated filter element for ongoing use. For heat-transfer fluids containing high concentrations of solids, bag filters or other high-surface-area designs may be preferred.

When intensive system cleaning is necessary, it is recommended to incorporate sound environmental, health and safety principles into the job plan to protect against exposure to hot fluid and vapors.

System drain

Adjust the fluid temperature to 93°C and shut down the heater. Continue operating the circulating pumps as long as possible during pump-out to keep loose solids and sludge in suspension.

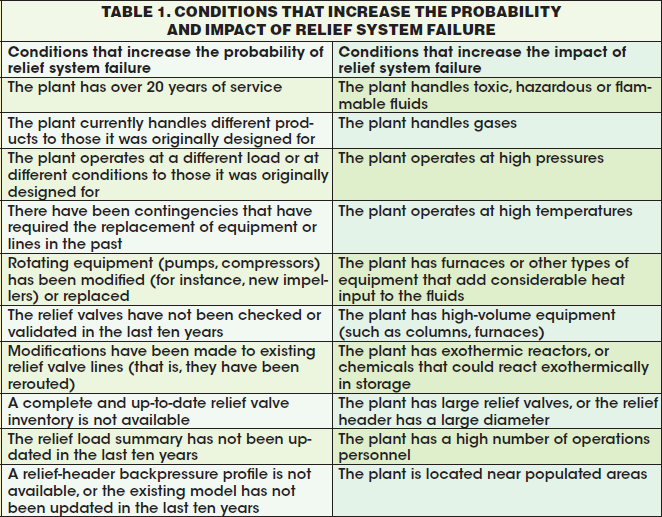

Drain the system through all low-point drains. If gravity draining is not sufficient or possible, compressed nitrogen can be used to effectively blow additional fluid from the system. Remove as much degraded heat-transfer fluid as possible to maximize the following cleaning techniques. Caution must be exercised to avoid contact with hot fluid and piping. Once the fluid has been drained from the system it should be stored, handled and disposed of according to the product MSDS (material safety data sheet) and your environmental, safety and health professionals’ guidance. The system may then be cleaned using one or more of the techniques in Table 1.

System ushing

If a strainer is not already present in the system return line that runs to the main circulating pumps, consider the addition of a fine-mesh strainer to protect the circulation pumps from solids that may be dislodged during cleaning.

When choosing a flushing fluid, ensure that it is compatible with the system components and the new replacement fluid. This can usually be determined by contacting the fluid manufacturer. In addition, avoid flush fluids that contain chlorine, as this may cause corrosion issues if a portion is left in the system.

Fill the system from the low points with the flushing fluid, including the expansion tank, to a normal operating level. Start circulating the entire system at ambient conditions to begin dissolving the organic solids and residual heat-transfer fluid.

Periodically check the return line strainer for plugging and buildup of solids that may have been released during system cleaning. In accordance with the manufacturer’s recommendations, increase the fluid temperature to maximize cleaning potential and continue circulating for the directed time period. Cool the flushing fluid, then drain it from the system through low points, ensuring that as much fluid is removed as possible, then dispose of it properly.

Chemical cleaning

In some situations, alternative cleaning methods are required, such as cleaning of a vapor-phase heat-transfer system. In these situations, chemical cleaning may be used as an alternative. In general, chemically cleaning a heat transfer system requires extra steps, higher cost, additional time and producessignificantly more waste. A general outline of a chemical cleaning procedure may include the following:

• Drain heat-transfer fluid from system

• Solvent flush circulation

• Drain solvent flush

• Acidic solution circulation

• Caustic and detergent solution circulation

• Flush with water

• Dry thoroughly

Mechanical cleaning

In some cases, such as when the system has been severely fouled by hard coke deposits or the lines are completely blocked, the above methods are inadequate for cleaning the system. In these cases, mechanical cleaning is most likely required.

Mechanical cleaning methods can include highpressure water jetting, wire brushing, mechanical scraping and sand or bead blasting.

After cleaning

Once the system has been drained completely, it should be inspected for solids that may have fallen out of suspension, especially in low-velocity areas.

Ensure that a side-stream filter is operational and properly maintained. If a side-stream filter is not present in the system, consider installing one to aid in solids removal during normal operation.

Refill the system with fresh heat-transfer fluid and start up using normal procedures. Residual moisture may be present from the drain, cleaning and start up procedures. Care should be taken to vent any moisture from the system by allowing

flow through the expansion tank where the moisture can flash and then vent. It is also suggested to employ inert gas blanketing of the expansion-tank vapor space to prevent moisture and air contamination of the fluid. This is usually put in place

after moisture has been vented and the system is brought up to operating temperature.

References and further reading

1. Beain, A., Heidari, J., Gamble, C.E., Properly Clean Out Your Organic Heat-Transfer Fluid System, Chem. Eng. Prog., May 2001, pp. 74–77.

2. Gamble, C.E., Cleaning Organic Heat Transfer Systems, Process Heating, Oct. 2002, pp. 39–41.

3.

Solutia Inc., “Therminol Information Bulletin no. 1: Cleaning Organic Heat Transfer Fluid Systems,” Pub. no. 7239011B, Solutia Inc., 2008.

4.

Solutia Inc., “Therminol Information Bulletin no. 3: Heat Transfer Fluid Filtration: How and Why,” Pub. no. 7239123B, Solutia Inc., 2004.

Editor’s note: Content for this edition of “Facts at Your Fingertips” was contributed by

Solutia Inc.